PCB Procurement & Supply

The PCB procurement team here at Walkbury have enormous experience and knowledge with circuit board design for manufacture and procurement services.

Our business has been thriving for over 40 years with huge investment in not only the best capital equipment required, but also the forging of key relationships with PCB suppliers over many years.

So please give us a call and let’s work together to increase your profits and lower your overheads.

“Top Quality Customer Care”

Our partners are able to deliver small, medium and large quantities of circuit boards at extremely cost-effective pricing. We also pass on that de-risking element where companies may choose the wrong supplier without experiencing them first-hand and validating the supplier properly of course.

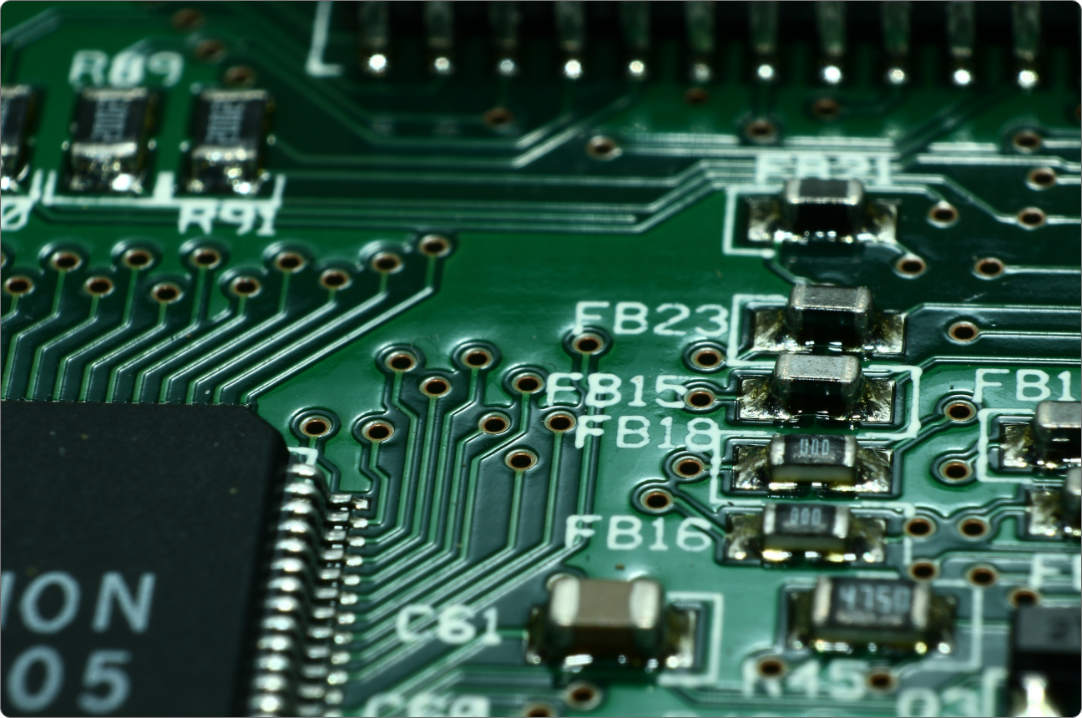

PCB Capabilities

ISO90001-200 Quality Certification which complies with American UL standards, ROHS, EU, SGS lead free production certification

- Up to 40 layers

- Board thickness max 10mm / min 0.2mm

- Copper thickness inner/outer 6oz / 10oz

- Material – FR4, PTFE, TG, Aluminium, RF, Microwave

- Flex/Flex-rigids – flexible material combinations

- Min mech drilling hole 0.15mm for board thickness <1.2 / 0.25mm for board thickness <2.5

- Min line spacing 3mil/3mil

- Min dialectric thickness 2mil

All our partners have been quality approved by our electronics manufacturing engineers with a deep knowledge of PCB manufacturing, procurement and supply.

Importantly, we understand the issues our manufacturing partners face regarding design, and ultimately manufacturing and assembly capability. This means everything in the PCB supply chain is audited and verified by Walkbury experts.

Despite continued growth and success, we deliberately retain a flat organisational structure affording us great flexibility, speed of communication and the ability to continually improve. There is no ‘red tape’ at Walkbury.

As a Walkbury customer you’ll have a dedicated Client Relationship Manager who is both suitably empowered and singularly tasked with ensuring that your needs are attended to. You will get the right answers to your questions from an expert who will work to understand your project needs in detail.

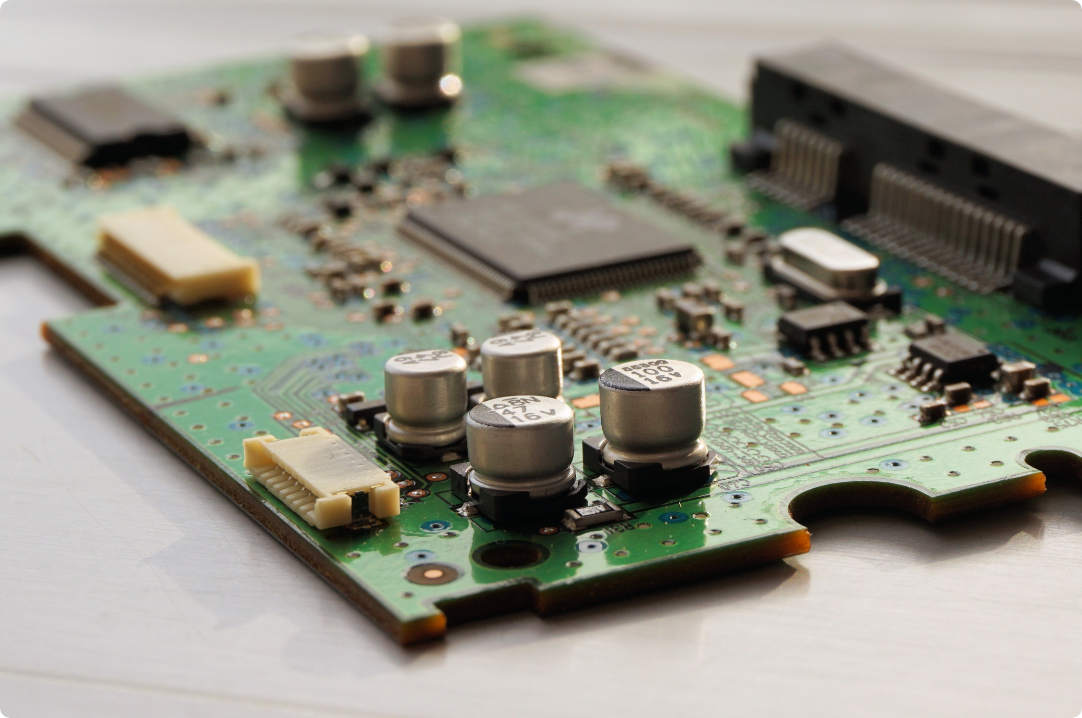

We believe that quality should be a given! Your assembly will be free from manufacturing defects and we go to great lengths to ensure that this is the case!

For example, every single SMT solder paste deposit our machines make is 100% optically inspected before a component is even placed. We employ state-of-the-art 3D AOI equipment to verify every single SMT placement that we make. Where appropriate, we’ll even hand deliver fragile or particularly sensitive assemblies. In short, nothing we do is left to chance.

“Nothing we do is left to chance”

But please don’t take us on our word alone, we’d like to welcome you on-site. Let us actively demonstrate our processes from start to finish. We really like to work with our customers as early in the process as practicable, this way we can offer the advice and expertise that our customers need. We are specialists in helping our customers ‘design for manufacture’.